- Details

- Category: Articles

Handling and Storage: Damage Risks and Mitigation Measures

The journey that a wind turbine blade takes from the factory to the turbine carries a risk of structural damage to the blade. From its work with multiple industry stakeholders, DNV has observed and investigated damage to, and the failure of, blades during the journey. Even relatively minor damage from transportation, handling or storage can worsen during operation. Such damage may result in the need for repair or, in severe cases, blade failure. Damage observed by DNV from transportation, handling and storage has ranged in severity from scratches to the blade coating where support fixtures made contact with the blade to damage to primary structural members of the blade, requiring replacement of the blade. Understanding these risks and how to mitigate them is important for protecting project investments and maximising blade durability.

The journey that a wind turbine blade takes from the factory to the turbine carries a risk of structural damage to the blade. From its work with multiple industry stakeholders, DNV has observed and investigated damage to, and the failure of, blades during the journey. Even relatively minor damage from transportation, handling or storage can worsen during operation. Such damage may result in the need for repair or, in severe cases, blade failure. Damage observed by DNV from transportation, handling and storage has ranged in severity from scratches to the blade coating where support fixtures made contact with the blade to damage to primary structural members of the blade, requiring replacement of the blade. Understanding these risks and how to mitigate them is important for protecting project investments and maximising blade durability.

By Matthew Malkin, Principal Engineer, DNV, USA

- Details

- Category: Articles

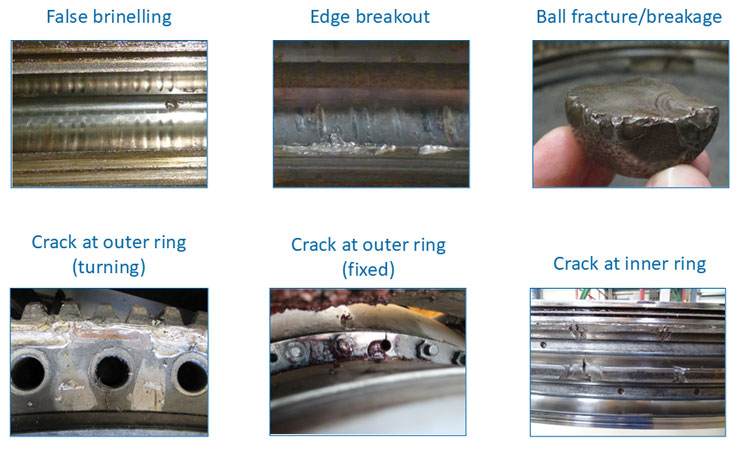

Challenges in Blade Bearing Operation

In recent years, the wind energy industry has faced a growing number of challenges related to the condition and durability of blade bearings. These critical components, which connect the rotor blades to the hub of a wind turbine, are exposed to highly dynamic loads during operation. Increasingly, operators and service providers have observed cracks, raceway damage and premature wear across various manufacturers and turbine models, including power classes between 2 and 8MW onshore and offshore. As turbines become older and are subjected to higher operational stresses, the mechanical loads acting on the blade bearings become more complex and variable. This accelerates fatigue processes and increases the risk of unexpected bearing failures.

By Moritz Hemmerlein and Hélène Guillerm, eolotec, Germany

- Details

- Category: Articles

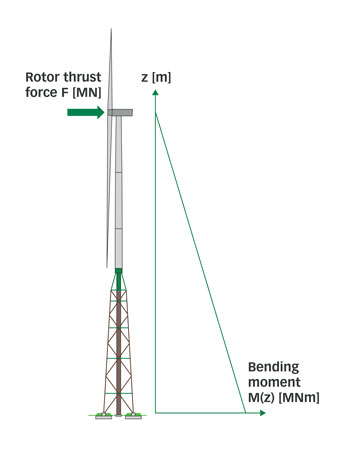

Timber Hybrid Towers for Wind Turbines

Timber Hybrid Towers for Wind Turbines

The demand for taller towers for wind turbines has been growing steadily for years. As tower heights increase so do the requirements for structural design and material efficiency. Conventional tower construction methods are increasingly reaching their technical and economic limits. Could timber hybrid towers be a suitable alternative to meet the increasing static requirements while enabling more efficient use of materials?

By Werner Mussnig and Roman Braun, Hasslacher Green Tower, Austria

- Details

- Category: Articles

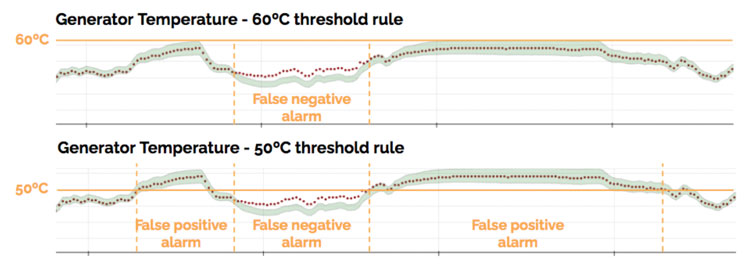

Moving Beyond Prediction with AI-Based Detection Models

The wind industry faces immense pressure to maximise asset availability and reduce operational expenditure. Traditional maintenance strategies, whether based on fixed schedules or simple alerts, often fall short, leading to costly unplanned downtime, unnecessary component replacements, and missed opportunities for optimisation. The challenge is moving from predictive models, which only forecast a failure, to prescriptive maintenance, which provides specific, actionable recommendations. This article provides a technical explanation of how artificial-intelligence-based detection models bridge this gap, using complex data to diagnose developing faults and prescribe a clear course of action, ultimately improving turbine reliability and reducing O&M costs.

By Silvio Rodrigues, Chief Innovation Officer and Co-founder, Jungle, Portugal

- Details

- Category: Articles

ZX 300e Wind Lidar Achieves IEC 21- to 200-Metre Classification

ZX 300e Wind Lidar Achieves IEC 21- to 200-Metre Classification

The global wind industry continues its advances towards ever-larger turbines. Whereas hub heights of 80 to 100 metres were once considered tall, today’s turbines are routinely installed at hub heights exceeding 120 to 160 metres, with rotor diameters of 170 to 200 metres. This scale of technology demands a measurement solution that can provide finance-grade wind data across the full rotor swept area. Without such measurement certainty, wind projects risk underperformance, increased cost of capital, and reduced investor confidence.

By Alex Woodward and James G. Downs, ZX Lidars, UK

- Details

- Category: Articles

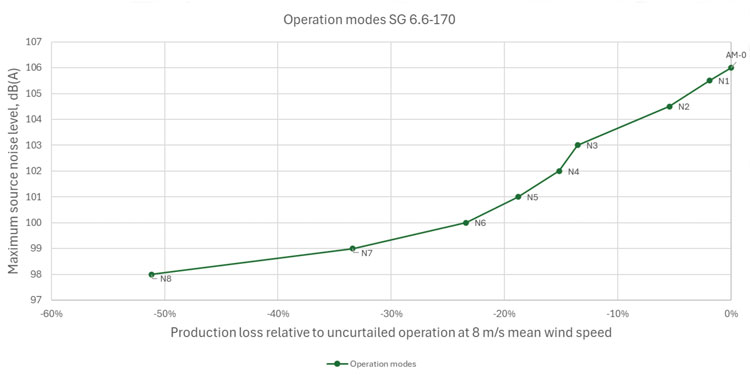

Production-Conditioned Algorithms Reduce Energy Losses

Noise curtailment of wind turbines is a common way to solve the problem of excess noise near wind farms. Reducing the received sound to comply with noise restrictions may sound simple, but if the goal is to minimise production loss, the problem can become rather complex. In this article, we demonstrate how a well-composed strategy using a production-conditioned optimisation algorithm can drastically minimise the potential production loss.

By Thomas Sørensen and Moritz Hildemann, EMD International, Denmark

- Details

- Category: Articles

How Engineers Brought Factory-Grade Repairs to the Field

How Engineers Brought Factory-Grade Repairs to the Field

Remanufacturing, the engineering process of restoring worn components to their original specification, has strong potential in wind energy O&M. Blade root inserts are critical load-transfer bushings that have become frequent failure points, presenting as loose bushings, caused by cyclic loading and resin matrix fatigue. Traditionally, on-site repair was impractical, forcing costly transport to OEMs or even blade scrapping. A 2025 case study demonstrated a viable alternative – Dutch We4Ce and Danish CNC Onsite developed a patented remanufacturing method enabling wind park operators to restore inserts on-site. In Europe, technicians were trained in precision drilling, resin infusion bonding, and bushing installation before a dedicated workshop was set up at a 50MW wind park in South Asia. Within weeks, the wind park was carrying out repairs independently. The method delivers up to 60% cost savings, reduces downtime, and eliminates heavy haul logistics. The transferability highlights remanufacturing’s potential as a mainstream O&M strategy, extending rotor blade life while advancing reliability and sustainability goals.

By Søren Kellenberger, CNC Onsite, Denmark and Edo Kuipers, We4Ce, the Netherlands