- Details

- Category: Articles

And the Modular Case

And the Modular CaseThe wind industry is primed for precast tower foundations. The economics point to significant returns to wind farm contractors and owners as the focus changes to longevity and expanding the construction and OEM delivery season.

By David McFeeters-Krone and Chris Fernandes, RUTE Foundation Systems, USA

- Details

- Category: Articles

New Techniques Provide Value Chain Savings

New Techniques Provide Value Chain SavingsNew industrial connectors enable the rear mounting of interfaces for switch cabinets. Using this option, all relevant connection steps can be carried out from the inside of a cabinet. Moreover, many installation processes can be shifted to the pre-assembly stage, thus helping to save expensive technician hours in the field. The termination technique can also accelerate processing. For example, the radial cage clamp used by Han ES Press enables a tool-free connection, in addition to offering options for bridging contacts directly on the insert.

By Carsten Edler, Industry Segment Manager Wind Energy, Harting Electric, Germany

- Details

- Category: Articles

Investigating New Designs Through Wake Loss and Cable Topology Optimisation

Investigating New Designs Through Wake Loss and Cable Topology OptimisationOffshore wind energy is an emerging technology that is becoming increasingly viable as technical and scientific improvements drive down the levelised cost of electricity making it more competitive with onshore wind technology and other forms of electricity generation.

By Bryce Wade, Canada

- Details

- Category: Articles

A New Technology Developed and Optimised for Offshore Use

A New Technology Developed and Optimised for Offshore UseThis article focuses on the main characteristics of two-bladed teetering hinged turbines on top of floating platforms. It highlights how the teetering hinge positively affects fatigue and loads caused by wind–wave interaction and summarises the cost-effective technological choices for the system features and installation method.

By Silvestro Caruso, Chief Technical Officer, Seawind Ocean Technology, The Netherlands

- Details

- Category: Articles

What Will Come After the Germany Renewable Energy Sources Act?

What Will Come After the Germany Renewable Energy Sources Act?In many places, operators and investors in Germany are asking, ‘What will come after the EEG (Renewable Energy Sources Act)?’ This means the time after the 20-year period with fixed feed-in tariffs. In contrast, in many countries around the globe there are no fixed feed-in rates governed by law at all – investors need to find offtakers for their eco-power from the first kilowatt-hour onward. This is where power purchase agreements (PPAs) come into place. On the other hand, such PPA structures are often also supported by tax or financing benefits or green quotas. Thus, what kind of prospects do PPAs offer for the German energy market?

Björn Broda, Head of Corporate Strategy, Communications & Public Affairs Department, juwi, Germany

- Details

- Category: Articles

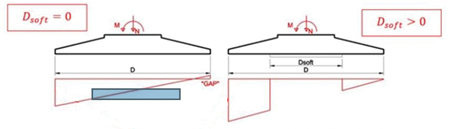

Engineering Approach to Designing New Solutions for Foundations

Engineering Approach to Designing New Solutions for FoundationsWith the increase in average turbine size witnessed by the global wind industry over the years, foundations have also become enormous. Therefore, innovation and expertise are crucial to remain competitive in an industry where optimisation is essential in order to reduce the costs associated with foundations.

By Alexander Martin, CEO, CTE Wind, France

- Details

- Category: Articles

A Telescopic Wind Tower With Reduced Environmental Impact

A Telescopic Wind Tower With Reduced Environmental ImpactA prototype of a telescopic pole for wind energy production with low environmental impact and its lifting system for a 60–250kW turbine and a height of 30 metres have been designed and manufactured. A telescopic tower, which is raised and lowered by automation or by remote control, allows differentiation of the presence of the generator within the landscape over time. The research target is the optimal design of the telescopic coupling, the maintenance of the preload, the rotational decoupling, the pairs of sleeves, the pegs and the bushes of the jack-up lifting system. All the components of the wind tower have been preliminarily analysed through finite element method stress computational analysis. The prototype was installed in Caltanissetta, Italy, and successfully tested.

By A. Pantano, T. Tucciarelli, N. Montinaro, A. Mancino, M. Sinagra, Università degli Studi di Palermo, Italy

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.