- Details

- Category: Articles

A Study of Delamination Under Various Loading Conditions

Wind turbine blades are typically manufactured from fibre-reinforced polymer (FRP) composites, and delamination failure can be an important issue in these structures. In extreme conditions, such as ice impacting, multiple delamination with a triangular shape is found in different parts of a blade. This delamination introduces local damage, which can then cause catastrophic failure under various loading conditions including buckling. Buckling and post-buckling are two loading conditions that can occur in large wind turbine blades due to gravitational, aerodynamic and centrifugal forces. In the work reported here, experimental studies of buckling and post-buckling failure in multi-delaminated composite beams were carried out. Laminated composite beams were pinned through their thickness using natural flax yarns to control delamination failure during the post-buckling process. Multi-delaminated composite beams were manufactured with laminate designs of [C90/G90]4 and [C0/G0]4 and tested to find the critical buckling load and post-buckling failure mode.

Wind turbine blades are typically manufactured from fibre-reinforced polymer (FRP) composites, and delamination failure can be an important issue in these structures. In extreme conditions, such as ice impacting, multiple delamination with a triangular shape is found in different parts of a blade. This delamination introduces local damage, which can then cause catastrophic failure under various loading conditions including buckling. Buckling and post-buckling are two loading conditions that can occur in large wind turbine blades due to gravitational, aerodynamic and centrifugal forces. In the work reported here, experimental studies of buckling and post-buckling failure in multi-delaminated composite beams were carried out. Laminated composite beams were pinned through their thickness using natural flax yarns to control delamination failure during the post-buckling process. Multi-delaminated composite beams were manufactured with laminate designs of [C90/G90]4 and [C0/G0]4 and tested to find the critical buckling load and post-buckling failure mode.

By Dr Hessam Ghasemnejad, School of Aerospace and Aircraft Engineering, Kingston University London, UK

Wind turbine blades are typically manufactured from fibre-reinforced polymer (FRP) composites, and delamination failure can be an important issue in these structures. In extreme conditions, such as ice impacting, multiple delamination with a triangular shape is found in different parts of a blade. This delamination introduces local damage, which can then cause catastrophic failure under various loading conditions including buckling. Buckling and post-buckling are two loading conditions that can occur in large wind turbine blades due to gravitational, aerodynamic and centrifugal forces. In the work reported here, experimental studies of buckling and post-buckling failure in multi-delaminated composite beams were carried out. Laminated composite beams were pinned through their thickness using natural flax yarns to control delamination failure during the post-buckling process. Multi-delaminated composite beams were manufactured with laminate designs of [C90/G90]4 and [C0/G0]4 and tested to find the critical buckling load and post-buckling failure mode.

Wind turbine blades are typically manufactured from fibre-reinforced polymer (FRP) composites, and delamination failure can be an important issue in these structures. In extreme conditions, such as ice impacting, multiple delamination with a triangular shape is found in different parts of a blade. This delamination introduces local damage, which can then cause catastrophic failure under various loading conditions including buckling. Buckling and post-buckling are two loading conditions that can occur in large wind turbine blades due to gravitational, aerodynamic and centrifugal forces. In the work reported here, experimental studies of buckling and post-buckling failure in multi-delaminated composite beams were carried out. Laminated composite beams were pinned through their thickness using natural flax yarns to control delamination failure during the post-buckling process. Multi-delaminated composite beams were manufactured with laminate designs of [C90/G90]4 and [C0/G0]4 and tested to find the critical buckling load and post-buckling failure mode.By Dr Hessam Ghasemnejad, School of Aerospace and Aircraft Engineering, Kingston University London, UK

- Details

- Category: Articles

STX Windpower Introduces a New Direct Drive Wind Turbine

The first direct drive wind turbine was introduced to the market in the early 1990s. This ‘direct drive’, as opposed to the traditional ‘geared type’, was seen as a challenging and expensive new technique, but it performed well. Now, after 20 years, it seems to be confirming its inherent superiority.

The first direct drive wind turbine was introduced to the market in the early 1990s. This ‘direct drive’, as opposed to the traditional ‘geared type’, was seen as a challenging and expensive new technique, but it performed well. Now, after 20 years, it seems to be confirming its inherent superiority.

By M. Huizer and N. te Welscher, STX Windpower B.V., The Netherlands

The first direct drive wind turbine was introduced to the market in the early 1990s. This ‘direct drive’, as opposed to the traditional ‘geared type’, was seen as a challenging and expensive new technique, but it performed well. Now, after 20 years, it seems to be confirming its inherent superiority.

The first direct drive wind turbine was introduced to the market in the early 1990s. This ‘direct drive’, as opposed to the traditional ‘geared type’, was seen as a challenging and expensive new technique, but it performed well. Now, after 20 years, it seems to be confirming its inherent superiority.By M. Huizer and N. te Welscher, STX Windpower B.V., The Netherlands

- Details

- Category: Articles

A Living Lab Smart Grid Demonstration

While a great deal has been said and written about smart grids in recent years, energy consulting firm KEMA has taken the initiative to set up and demonstrate the first total-concept living lab smart grid in its PowerMatching City project. After a year in the first phase of operations, the initial results of the field test in a village just outside Groningen in the Netherlands show that the system was a success.

While a great deal has been said and written about smart grids in recent years, energy consulting firm KEMA has taken the initiative to set up and demonstrate the first total-concept living lab smart grid in its PowerMatching City project. After a year in the first phase of operations, the initial results of the field test in a village just outside Groningen in the Netherlands show that the system was a success.

By Rolf van Stenus, Corporate Press Officer, KEMA Nederland BV, The Netherlands

While a great deal has been said and written about smart grids in recent years, energy consulting firm KEMA has taken the initiative to set up and demonstrate the first total-concept living lab smart grid in its PowerMatching City project. After a year in the first phase of operations, the initial results of the field test in a village just outside Groningen in the Netherlands show that the system was a success.

While a great deal has been said and written about smart grids in recent years, energy consulting firm KEMA has taken the initiative to set up and demonstrate the first total-concept living lab smart grid in its PowerMatching City project. After a year in the first phase of operations, the initial results of the field test in a village just outside Groningen in the Netherlands show that the system was a success.By Rolf van Stenus, Corporate Press Officer, KEMA Nederland BV, The Netherlands

- Details

- Category: Articles

Understanding and Quantifying Wind Quality

One of the primary aspects of developing an effective operational wind farm, both onshore and offshore, is being able to understand and quantify wind quality across the site of interest. This involves the collection of as much information as is reasonable over a given timeframe, from a range of points horizontally and vertically across the area. The information gathered can be from a range of sources, in different formats and communicated by a variety of methods. It therefore poses a challenge not only to the site developers but also, in due course, to the financiers and lenders who are making investment decisions on the basis of the data collected. However, overcoming this challenge result in a large amount of very valuable data, ultimately leading to finance-grade wind resource assessment for the wind farm.

One of the primary aspects of developing an effective operational wind farm, both onshore and offshore, is being able to understand and quantify wind quality across the site of interest. This involves the collection of as much information as is reasonable over a given timeframe, from a range of points horizontally and vertically across the area. The information gathered can be from a range of sources, in different formats and communicated by a variety of methods. It therefore poses a challenge not only to the site developers but also, in due course, to the financiers and lenders who are making investment decisions on the basis of the data collected. However, overcoming this challenge result in a large amount of very valuable data, ultimately leading to finance-grade wind resource assessment for the wind farm.

By Oisin Brady, Director of Tools & Methodology, and Alex Woodward, Product Development Manager, Natural Power, UK

One of the primary aspects of developing an effective operational wind farm, both onshore and offshore, is being able to understand and quantify wind quality across the site of interest. This involves the collection of as much information as is reasonable over a given timeframe, from a range of points horizontally and vertically across the area. The information gathered can be from a range of sources, in different formats and communicated by a variety of methods. It therefore poses a challenge not only to the site developers but also, in due course, to the financiers and lenders who are making investment decisions on the basis of the data collected. However, overcoming this challenge result in a large amount of very valuable data, ultimately leading to finance-grade wind resource assessment for the wind farm.

One of the primary aspects of developing an effective operational wind farm, both onshore and offshore, is being able to understand and quantify wind quality across the site of interest. This involves the collection of as much information as is reasonable over a given timeframe, from a range of points horizontally and vertically across the area. The information gathered can be from a range of sources, in different formats and communicated by a variety of methods. It therefore poses a challenge not only to the site developers but also, in due course, to the financiers and lenders who are making investment decisions on the basis of the data collected. However, overcoming this challenge result in a large amount of very valuable data, ultimately leading to finance-grade wind resource assessment for the wind farm.By Oisin Brady, Director of Tools & Methodology, and Alex Woodward, Product Development Manager, Natural Power, UK

- Details

- Category: Articles

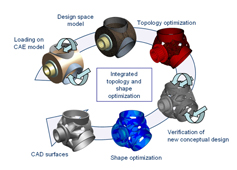

Topology and Shape Optimisation to Speed Up Component Development

This article addresses the challenging topic of new conceptual designs for wind turbine components, which aim to ensure price competitiveness as well as best-in-class structural performance. The focus is on the non-parametric optimisation approaches of the optimisation tool TOSCA Structure, created by the FE-DESIGN company. The main subjects of this article are two of the modules in that software tool: TOSCA Structure.topology and TOSCA Structure.shape.

This article addresses the challenging topic of new conceptual designs for wind turbine components, which aim to ensure price competitiveness as well as best-in-class structural performance. The focus is on the non-parametric optimisation approaches of the optimisation tool TOSCA Structure, created by the FE-DESIGN company. The main subjects of this article are two of the modules in that software tool: TOSCA Structure.topology and TOSCA Structure.shape.

By Claus B.W. Pedersen and Florian Jurecka, FE-DESIGN, Germany

This article addresses the challenging topic of new conceptual designs for wind turbine components, which aim to ensure price competitiveness as well as best-in-class structural performance. The focus is on the non-parametric optimisation approaches of the optimisation tool TOSCA Structure, created by the FE-DESIGN company. The main subjects of this article are two of the modules in that software tool: TOSCA Structure.topology and TOSCA Structure.shape.

This article addresses the challenging topic of new conceptual designs for wind turbine components, which aim to ensure price competitiveness as well as best-in-class structural performance. The focus is on the non-parametric optimisation approaches of the optimisation tool TOSCA Structure, created by the FE-DESIGN company. The main subjects of this article are two of the modules in that software tool: TOSCA Structure.topology and TOSCA Structure.shape.By Claus B.W. Pedersen and Florian Jurecka, FE-DESIGN, Germany

- Details

- Category: Articles

Wind Power Sites’ Interconnections to Electric Utilities’ Distribution Networks

More and more electric utilities are interconnecting renewable energy production sites to their grids, and this includes smaller wind generator installations connecting to the electric utilities’ distribution network. This article describes the main technical components and the main features of the UTAPP, a remote-controlled distribution network interconnection application.

By Mario Bastien, Automation Engineer, Hydro-Québec Distribution, Canada

More and more electric utilities are interconnecting renewable energy production sites to their grids, and this includes smaller wind generator installations connecting to the electric utilities’ distribution network. This article describes the main technical components and the main features of the UTAPP, a remote-controlled distribution network interconnection application.

By Mario Bastien, Automation Engineer, Hydro-Québec Distribution, Canada

- Details

- Category: Articles

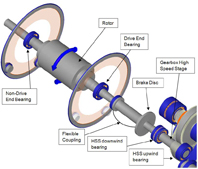

Understanding the Effects of Drive Train Misalignment on Bearing Fatigue Life

Improving the reliability of wind turbines is an essential component in the bid to minimise the cost of energy, especially for offshore wind due to the difficulties associated with access. Numerous studies have shown that wind turbine generator failure rates are unacceptably high, particularly given the long downtime incurred per failure. However, generator failures have, to date, received relatively little attention in the wind industry with the focus generally having been on the blades and the gearbox. There is evidence that the bearings are the most important source of generator failures; one important root cause of bearing failure is misalignment. An overview of publicly available wind turbine reliability data is presented in this article, and the importance of drive train misalignment is described.

Improving the reliability of wind turbines is an essential component in the bid to minimise the cost of energy, especially for offshore wind due to the difficulties associated with access. Numerous studies have shown that wind turbine generator failure rates are unacceptably high, particularly given the long downtime incurred per failure. However, generator failures have, to date, received relatively little attention in the wind industry with the focus generally having been on the blades and the gearbox. There is evidence that the bearings are the most important source of generator failures; one important root cause of bearing failure is misalignment. An overview of publicly available wind turbine reliability data is presented in this article, and the importance of drive train misalignment is described.

By Matthew Whittle, University of Durham, UK

Improving the reliability of wind turbines is an essential component in the bid to minimise the cost of energy, especially for offshore wind due to the difficulties associated with access. Numerous studies have shown that wind turbine generator failure rates are unacceptably high, particularly given the long downtime incurred per failure. However, generator failures have, to date, received relatively little attention in the wind industry with the focus generally having been on the blades and the gearbox. There is evidence that the bearings are the most important source of generator failures; one important root cause of bearing failure is misalignment. An overview of publicly available wind turbine reliability data is presented in this article, and the importance of drive train misalignment is described.

Improving the reliability of wind turbines is an essential component in the bid to minimise the cost of energy, especially for offshore wind due to the difficulties associated with access. Numerous studies have shown that wind turbine generator failure rates are unacceptably high, particularly given the long downtime incurred per failure. However, generator failures have, to date, received relatively little attention in the wind industry with the focus generally having been on the blades and the gearbox. There is evidence that the bearings are the most important source of generator failures; one important root cause of bearing failure is misalignment. An overview of publicly available wind turbine reliability data is presented in this article, and the importance of drive train misalignment is described.By Matthew Whittle, University of Durham, UK

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.