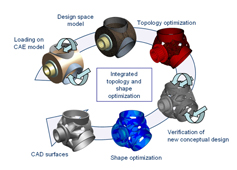

Topology and Shape Optimisation to Speed Up Component Development

This article addresses the challenging topic of new conceptual designs for wind turbine components, which aim to ensure price competitiveness as well as best-in-class structural performance. The focus is on the non-parametric optimisation approaches of the optimisation tool TOSCA Structure, created by the FE-DESIGN company. The main subjects of this article are two of the modules in that software tool: TOSCA Structure.topology and TOSCA Structure.shape.

This article addresses the challenging topic of new conceptual designs for wind turbine components, which aim to ensure price competitiveness as well as best-in-class structural performance. The focus is on the non-parametric optimisation approaches of the optimisation tool TOSCA Structure, created by the FE-DESIGN company. The main subjects of this article are two of the modules in that software tool: TOSCA Structure.topology and TOSCA Structure.shape.

By Claus B.W. Pedersen and Florian Jurecka, FE-DESIGN, Germany

This article addresses the challenging topic of new conceptual designs for wind turbine components, which aim to ensure price competitiveness as well as best-in-class structural performance. The focus is on the non-parametric optimisation approaches of the optimisation tool TOSCA Structure, created by the FE-DESIGN company. The main subjects of this article are two of the modules in that software tool: TOSCA Structure.topology and TOSCA Structure.shape.

This article addresses the challenging topic of new conceptual designs for wind turbine components, which aim to ensure price competitiveness as well as best-in-class structural performance. The focus is on the non-parametric optimisation approaches of the optimisation tool TOSCA Structure, created by the FE-DESIGN company. The main subjects of this article are two of the modules in that software tool: TOSCA Structure.topology and TOSCA Structure.shape.By Claus B.W. Pedersen and Florian Jurecka, FE-DESIGN, Germany