Reliable Verification of Design Parameters at Prototype and Serial Turbines

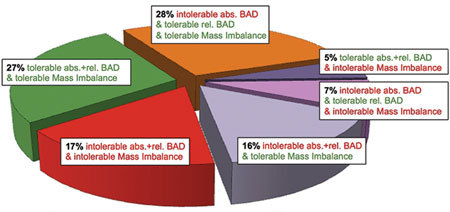

For reasons of cost reduction, modern large wind turbines and blades are designed to use less material and to make use of new materials. They are designed using new simulation tools and smaller safety factors, going beyond established knowledge. Therefore, turbine type certification requires simulation validation by real-life prototype measurements to prove that design dimensions (e.g. clearance between blade tip and tower), parameters and assumptions assure safe operation during the planned service life. For safe and reliable operation, every serial turbine also has to comply with certified design parameters. This keeps O&M costs and lifetime consumption low, despite unmanned 24/7 operation in remote areas. Hence, highly accurate but also cost efficient and safe measuring methods are needed to avoid excess fatigue loads, such as those from resonance issues related to the tower’s natural frequencies or intolerably high rotor imbalance and blade angle deviation. For these applications, video-based analysis is a suitable method to measure motion and vibration.

For reasons of cost reduction, modern large wind turbines and blades are designed to use less material and to make use of new materials. They are designed using new simulation tools and smaller safety factors, going beyond established knowledge. Therefore, turbine type certification requires simulation validation by real-life prototype measurements to prove that design dimensions (e.g. clearance between blade tip and tower), parameters and assumptions assure safe operation during the planned service life. For safe and reliable operation, every serial turbine also has to comply with certified design parameters. This keeps O&M costs and lifetime consumption low, despite unmanned 24/7 operation in remote areas. Hence, highly accurate but also cost efficient and safe measuring methods are needed to avoid excess fatigue loads, such as those from resonance issues related to the tower’s natural frequencies or intolerably high rotor imbalance and blade angle deviation. For these applications, video-based analysis is a suitable method to measure motion and vibration.

By Anke Grunwald, Christoph Heilmann and Michael Melsheimer, BerlinWind GmbH, Germany